Solar PV Plant Layout for best Performance and Profitability

Optimum system configuration and layout design are essential to achieve successful long-term operation and targeted returns on investments. Achieving the best performance of a Solar PV System is challenging and requires detailed modelling and design by experienced professionals.

Based on Forte Renewables´ experience, this Insight will discuss the main aspects, requirements and design parameters (e.g. Ground Coverage Ratio (GCR), shading, row spacing, Albedo, Cabling, Eco System, etc.) for improving the design of a Solar PV System and its Plant Layout.

Design Considerations

Investors expect their Solar PV System to have best possible performance during the design lifetime. Configuration and layout needs to be designed in an optimum way to get best solar radiation, minimal shading, lowest temperature, higher security while minimising CAPEX and OPEX.

Not many studies have focused on spatial layout of Solar PV Systems even though it may significantly affect whether a system can achieve its highest potential. Modelling the spatial layout of a PV System requires site survey input data such as topography, soil resistance, etc. along with Geographical Information Systems (GIS) analysis to identify the optimal placement of multiple solar PV panels.

The design of a PV System layout needs to take into account the topography and environment restriction of the site. Traditional Software Simulation Tools, for Annual Energy Prediction (AEP), such as PVSyst, consider input parameters, such as Ground Coverage Ratio (GCR) and DC:AC Ratio but not the boundaries, restrictions and obstacles to solar irradiation that can only be inspected through a detailed site survey including topographic survey. The final layout of a PV System can only be obtained after successive refinements of simulations and site surveys.

Tracking Systems and Shading

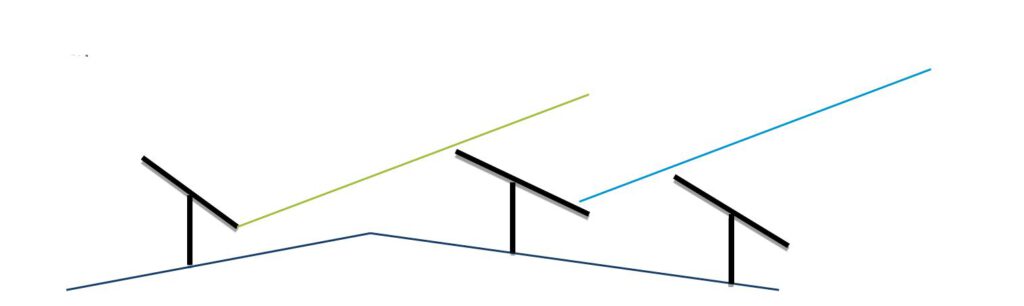

One-Axis (N-S) Tracking Systems, which are normally used by Utility Scale Solar Plants, improves Energy Yield and have short-term payback but many aspects need to be considered in their selection and design. The flatter the terrain the better the energy yield but this general condition will not always apply. Recently trackers have become more intelligent and some systems can be controlled, through software, the tilt angle of each string changes independently, aiming to maximize solar radiation capture and minimize shading from neighbouring rows:

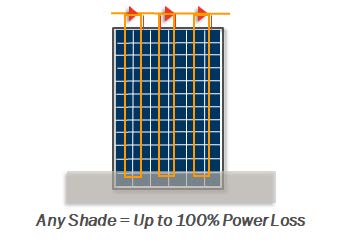

C-Si Modules do not respond linearly to shading and are protected by bypass diodes. In order to avoid early morning and late afternoon shading, Tracking Systems use the “Backtracking” function that adjusts the tilt for the “no-shading angle”. Backtracking results in worse angle of the radiation incidence but avoids shading and activation of bypass diodes.

C-Si PV Cells

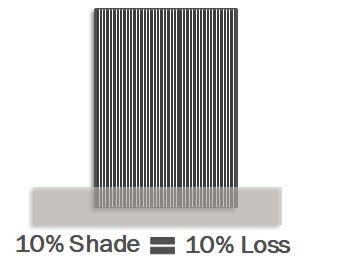

CdTe PV Cells

PV Modules with Thin Film Technologies such as CdTe respond linearly to shade and do not need “Backtracking” since power loss due to shading is directly proportional to the shaded area. In this case, trackers should aim to get the best radiation angle.

Albedo, Cabling and Drainage Systems

PV Modules have increased in size and bifaciality types have become usual on C-Si PV Modules, making the plant layout design even more complex. The surface Albedo is very important to Energy Prediction of PV Systems for both Monofacial and Bifacial Modules but, for the latter, it is critical since radiation on the rear side of the module contributes to power generation. Albedo can vary along the site and season but simulation tools use one single value. Using an incorrect Albedo factor in simulation processing may put at risk a project´s ROI.

The Ecosystem or EBoS is also a component that needs to be very deeply studied and designed. The configuration of DC- Wiring Harnesses and DC Combiner Boxes Systems is extremely relevant to minimize losses and, together with the grounding system, maximize protection. The length of cables should be minimised.

Drainage and Earthing Systems are extremely important to protect the plant against erosion, storms and lightning strikes. The Civil and Electrical BoP designs need to be carefully developed and reviewed by experienced engineers. Historically many PV Systems needed to rebuild these systems after extreme climate events which due to climate warming are becoming more common than historic statistics would suggest.

Conclusions

Designing the layout of an Utility Scale Solar PV System is complex since there are many options of configurations and design parameters. Software Simulation Tools can be used with multiple parameters and pieces of equipment, but the final System Configuration and layout need to be continuously refined after results of site topographical studies, analysis of restrictions, potential shades, Albedo, etc. Forte Renewables professionals have worked on the design and layout configurations of Solar PV Systems in many continents and can help its clients to obtain optimised design, mitigating the risks of jeopardising financial results.